At LEDwise, Quality matters

At LEDwise, Quality mattersLEDwise factory is managed under the standard ISO9001:2015, and follows ISO14001:2015 Environmental Quality System.

To make a reliable strip light, inspection and test procedure are seen through the whole process from raw material to a finished product. Our inspection and tests include

• Incoming material inspection

• In-line QC

• Flame retardant performance test

• Aging test

• High and low temperature

• Insulation test

• Lifespan test

• Reliability test

• Safety test

• IP test

• Optical test

• Contact current test

• Anti-static ability test

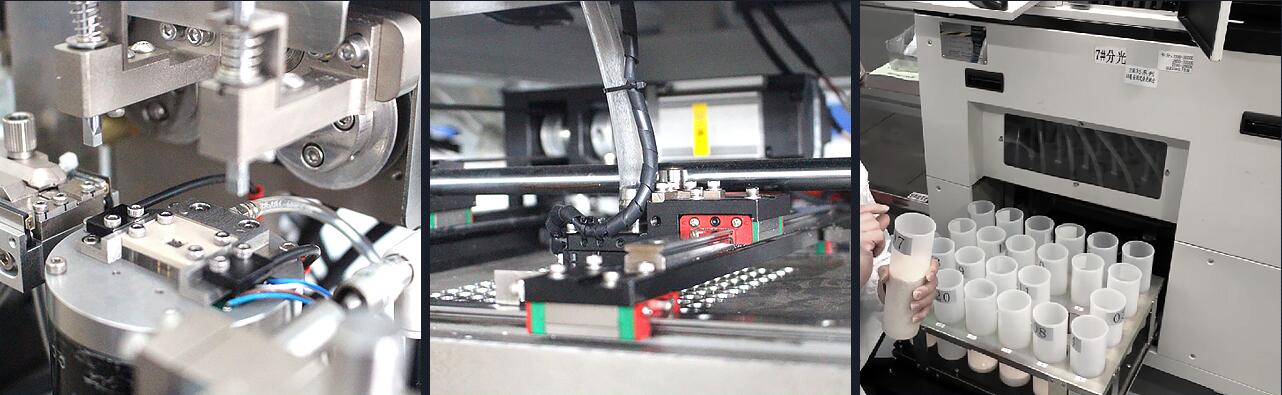

Our main facilities and equipments to ensure conducting the crucial tests include

• Hi-pot test machine

• Thermal shock test machine

• Aging test facility

• Lighting surge tester

• Integrated sphere

• IES Room

The LED chip is the most important parameter to identify strip light quality. Issues like light decay, dark spot, light spot, color difference are all in varying degrees related to it.

The binning process sorts the LEDs and group the lights with similar categories or bins defined by the similarity in lumen, color and voltage.

More than two-thirds of our customers set a high standard on LED chips. It enables us to buy LEDs in one bin in massive quantity. Through one year after another cooperation, we have created fairly good credit and trust both from our customers and suppliers. Thus, compared to many other suppliers, we buy LED chips at the same level at an unbeatable price.